1

Mechanical Machining

We machine enclosures to your precise drawings. You bear no risk of rejects and benefit from cost-effective production, fast delivery times, and consistent quality – with a minimum order quantity of just one piece.

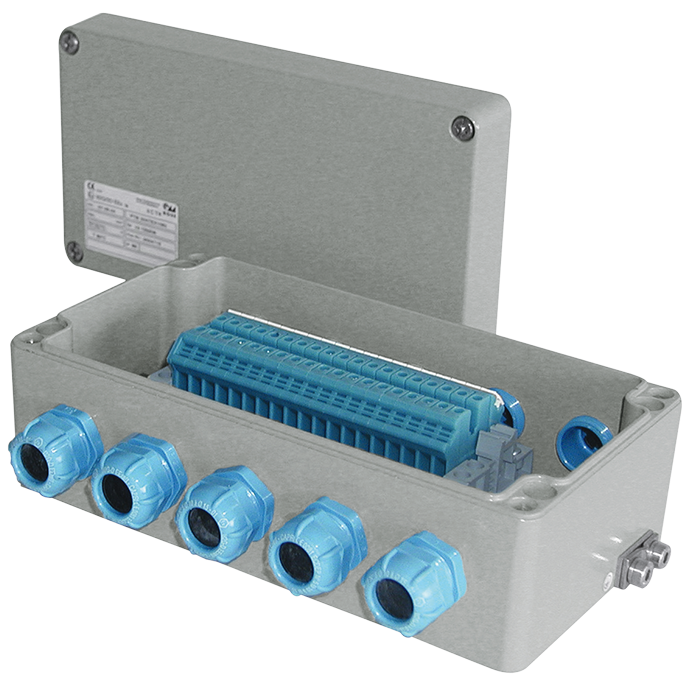

When operating in hazardous, explosive environments, our ATEX enclosures are the recommended solution. These explosion-proof enclosures lead in safety, offering optimum protection for your components against gas, dust, and water ingress. They are available in various temperature classes and dust/gas protection ranges, tailored to the material, installed components, and environment.

For Ex ia and Ex e applications – pre‑assembled or empty, sizes 64×58×34 mm to 600×600×200 mm

Glass‑fibre‑reinforced polyester enclosures for ATEX‑rated environments

ATEX‑ and IEC‑compliant stainless‑steel enclosures for aggressive environments

Glass‑fibre‑reinforced polyester cabinets for ATEX‑rated environments

remium stainless‑steel cabinets, ATEX‑certified for aggressive environments

ATEX‑compliant 1.4404/316L stainless‑steel flange enclosures for oil and gas applications, featuring a robust base, hinged lid, detachable flange plates and integrated earthing

Fibreglass‑reinforced polyester flanged enclosures for ATEX‑rated environments

Glass‑fibre‑reinforced polyester, ATEX‑certified enclosures for hazardous areas

Services

Discover how our expert services can elevate the performance and reliability of your ATEX enclosures. With our hands-on approach and proven expertise, we deliver tailored solutions that streamline every step – from design and production through to assembly and logistics – ensuring you get the best quality and value every time.