1

Mechanical Machining

We machine enclosures to your precise drawings. You bear no risk of rejects and benefit from cost-effective production, fast delivery times, and consistent quality – with a minimum order quantity of just one piece

The various series offer the best possible protection for your electronics in different application areas.

Electronic enclosures are distinguished by their flexibility and optimal compatibility with electronic components and printed circuit boards. The enclosure materials vary according to the application. For sensor or radio applications, plastic enclosures are preferred to ensure reliable data transmission, whereas aluminium housings offer enhanced EMC protection against interfering radiation and signals. Early selection of the appropriate enclosure during the development phase facilitates easier and more cost-effective integration of electronics. Unfortunately, insufficient attention is often given to the enclosure during early design, despite its vital role in both product functionality and marketing appeal. Our diverse series provide tailored protection across various application areas. If you wish to distinguish your product with a unique design, bespoke colours, and specialised materials, we offer our extensive experience in custom enclosure development. We manage the complete process – from design and engineering through prototyping to final production.

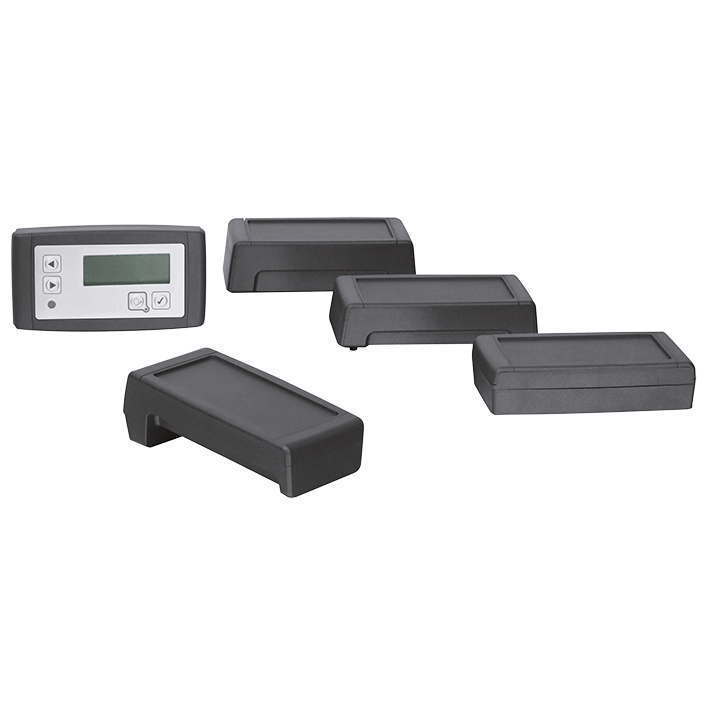

Highly versatile enclosure system – sleek design for applications beyond wireless

Contemporary design for displays and touchscreens

Intelligent, versatile enclosures for modern IoT sensors

Modular components for wall‑mounted or handheld assemblies

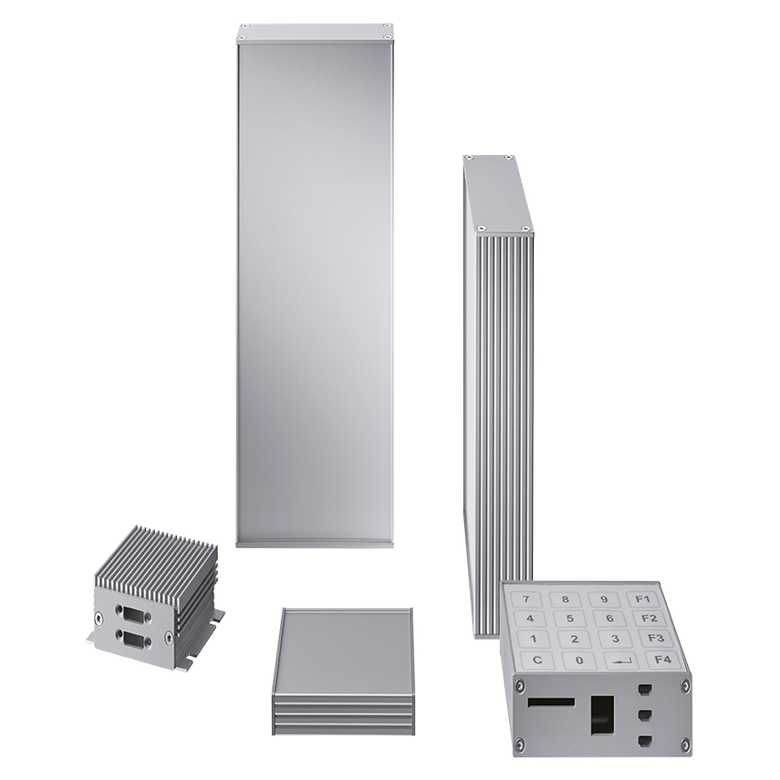

Versatile, robust aluminium profile enclosure for modular configurations

Ideal for data acquisition and processing applications

Aluminium profile enclosures in a range of configurations

Versatile enclosures for a wide range of electronic applications

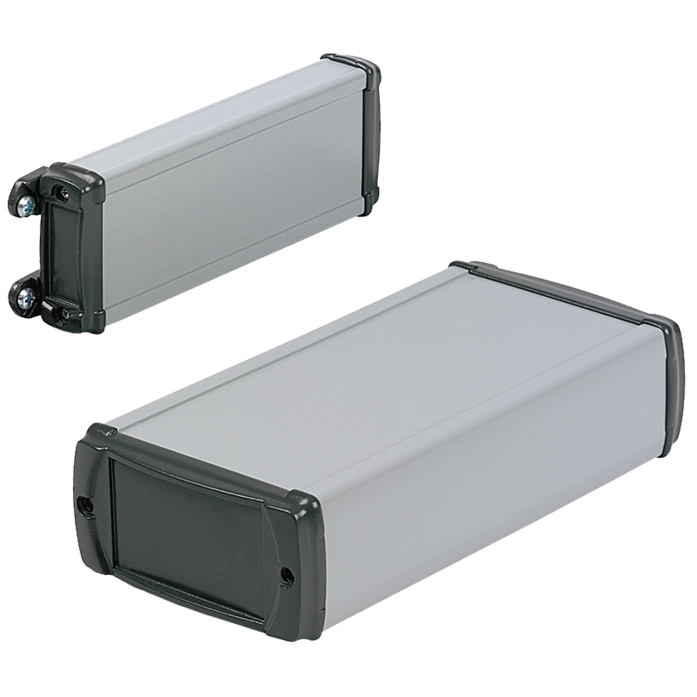

Customisable profile enclosure with shock‑protection seals and additional options

Wall‑mount enclosure with dedicated terminal compartment

Ideal for measurement and control technology applications

Simple, cost‑effective desktop enclosure for electronics

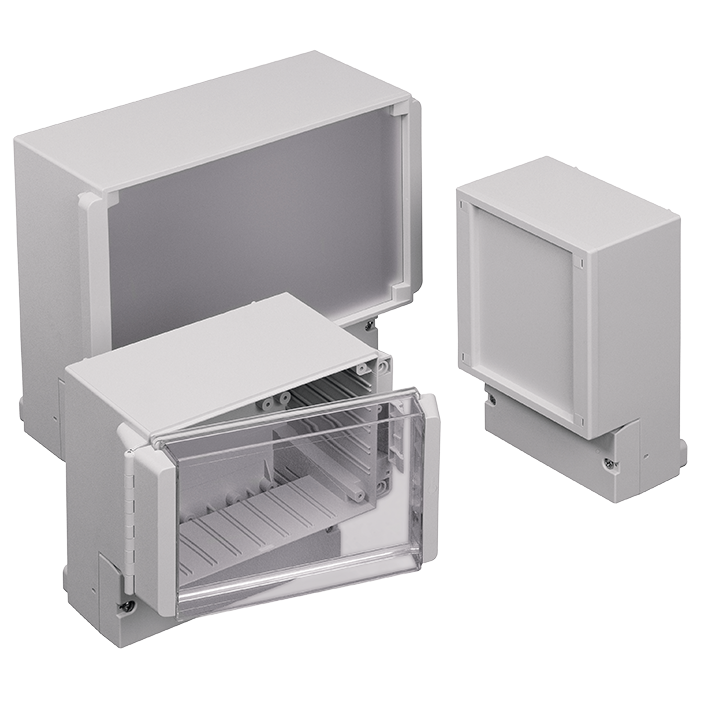

Featuring adjustable‑height mounting kits

Sleek design, available with or without ventilation slots

Ideal for wall‑mount, tabletop or portable use

Cost‑effective enclosure for electronic applications

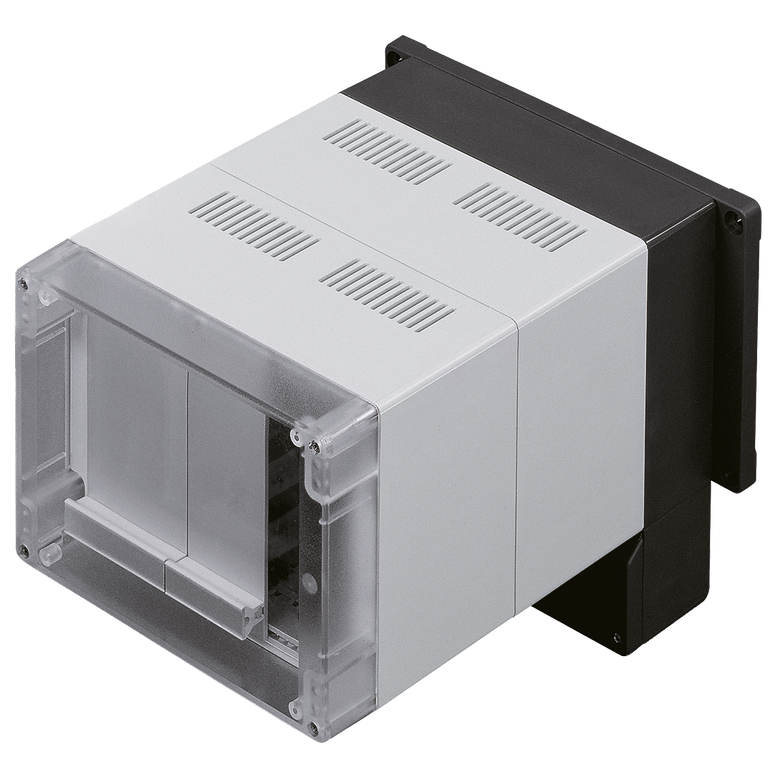

Panel‑mount enclosure compliant with DIN IEC 61554

Suitable for panel, tabletop, wall and desk mounting

For data, PC, measurement and control technology applications

High‑quality enclosure with an innovative design

Modular, kit‑based enclosure design

Modular, expandable card enclosure system

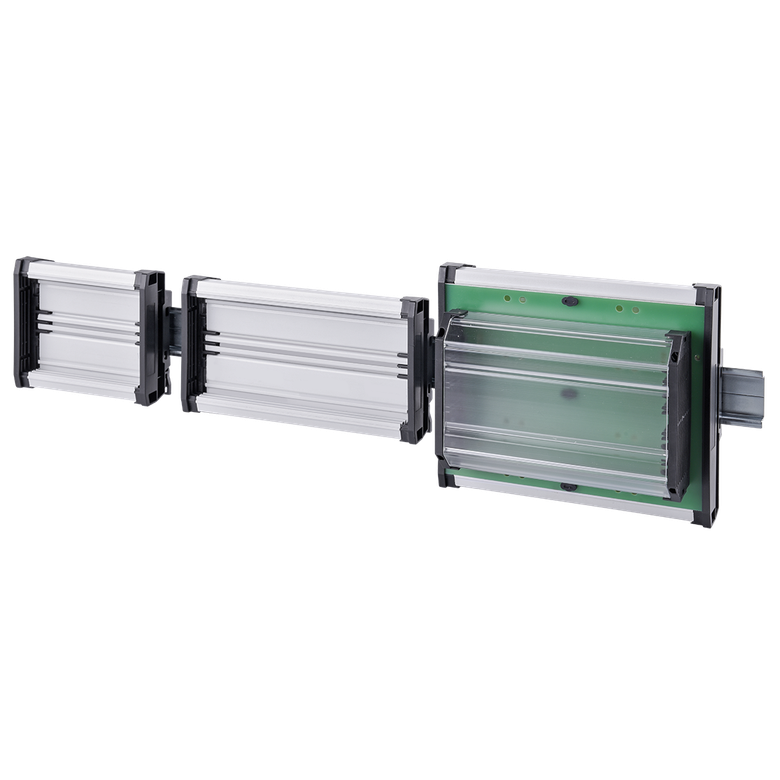

Modular aluminium profile enclosure for DIN‑rail mounting

DIN‑rail enclosure offering maximum mounting space

Modular top-hat rail enclosure with form factor according to DIN 43880

Streamlined DIN‑rail design minimises installation time and effort

Modular assembly with DIN‑rail bus connectors and selectable terminal blocks

Modular polyamide (UL 94 V‑0) DIN‑rail enclosure

Modular DIN‑rail enclosure system

Enclosures subracks and front panels

Services

Discover how our expert services can elevate the performance and reliability of your electronic enclosures. With our hands-on approach and proven expertise, we deliver tailored solutions that streamline every step – from design and production through to assembly and logistics – ensuring you get the best quality and value every time.