1

Mechanical Machining

We machine enclosures to your precise drawings. You bear no risk of rejects and benefit from cost-effective production, fast delivery times, and consistent quality – with a minimum order quantity of just one piece

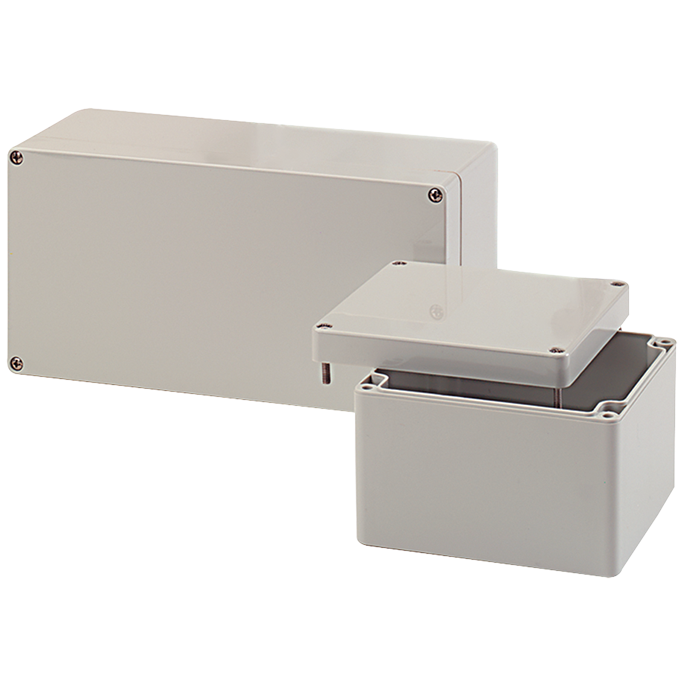

Plastic enclosures are suitable for harsh and demanding environments. They have been used successfully for decades in mechanical engineering, tunnel construction, vehicle construction or measurement and control technology. The enclosures are available in polyester, ABS, polycarbonate and polyamide. Most of the enclosures are available with protection class IP66. In addition, versions as flange enclosures and small control cabinets are available. All industrial enclosures can also be mounted as wall enclosures.

)

Robust glass‑fibre‑reinforced polyester enclosure

Premium polycarbonate, IP68‑rated enclosures – dimensionally stable and impact‑resistant

Cost‑effective ABS, IP66‑rated enclosures with versatile dimensions and accessories

Polyester enclosures for railway technology

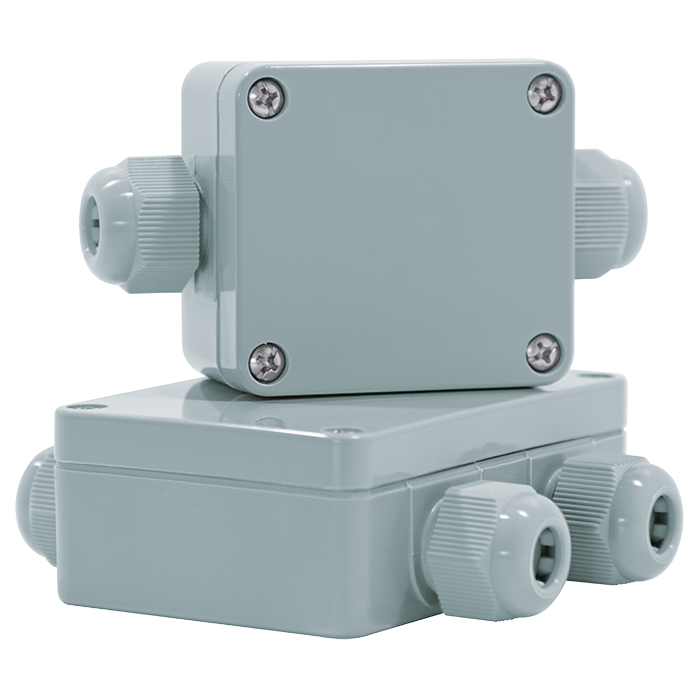

Polyamide enclosure with molded-on cable glands

Thermoplastic enclosures featuring smooth sidewalls

Thermoplastic enclosures with pre‑formed cable gland knockouts

Durable, corrosion‑resistant polyester control cabinets

Compact control cabinets with concealed external hinges

Rugged cabinets for harsh environments

Available with or without viewing windows

Plastic enclosures with flanged openings

Plastic enclosures with flanged apertures

)

The best known application of plastic enclosures in industry, is as terminal boxes or distribution boxes. The equipped terminals on the mounting rail are mounted directly in the lower part on the webs provided for this purpose.

In the side walls, the threads are cut according to customer specifications and, if desired, immediately equipped with cable glands. The cover can be machined for pushbuttons and switches. Due to the wide range of terminal assembly options in terms of number and type, we offer over 100 different sizes of industrial enclosures.

We also offer different materials depending on the applications. Polyester enclosures are suitable for very rough applications such as outdoor, tunnel construction, railroad technology or construction machinery.

Plastic enclosures made of ABS, polyamide or polycarbonate for any indoor application. We are happy to support you in making the right choice.

Services

Discover how our expert services can elevate the performance and reliability of your plastic enclosure. With our hands-on approach and proven expertise, we deliver tailored solutions that streamline every step – from design and production through to assembly and logistics – ensuring you get the best quality and value every time.