)

Linear Actuator Lambda

Stroke: max. 600mm | Force: max. 6,000N | Speed max. 38mm/s

Features

Synchronization Control

Direction of movement selection by supply voltage polarity

Position Feedback by Integrated Limit Switch or Potentiometer options

Compact, robust housing design with IP66 protection class

Linear Actuator Lambda – Economic Actuator with High Force

The Lambda electric linear actuator is a high-force, compact solution, offering up to 6,000 N of thrust in a versatile, modular design. It is built for extreme conditions, with resistance to wetness, dirt, heat, and cold, making it suitable for demanding environments. The Lambda linear actuator features optional safety functions like pinch protection, manual disengagement, and self-locking for user protection. It is customizable with various stroke lengths, gearing options, and can be adapted for different applications, from industrial machinery to offshore and agricultural equipment.

Constructed with a durable polymer IP66-rated housing and stainless-steel lift tube, the Lambda actuator ensures reliable operation even in harsh conditions. It’s commonly used in agricultural machinery, off-highway vehicles, and marine technology, with applications such as moving flaps, regulating fresh air ventilation in buildings, or opening service doors on aircraft. Its rugged design and optional position feedback make it ideal for industries requiring precision and durability.

Technical Data

General Data | |

|---|---|

| Force | Max. 6,000 N (Push), 4,000 N (Pull) |

| Speed | Max. 38 mm/s |

| Stroke Length | Min. 15 mm – max. 600 mm |

| Installation Dimension (A) | Smaller than stroke 400 mm = stroke +175 mm | Greater than or equal to stroke 400 mm = stroke +22 5mm |

| Motor Voltage | 12V DC, 24V DC |

| Degree of Protection | IP66 |

| Duty Cycle | 10% |

| Position Feedback | Optional Integrated Limit Switch or Potentiometer |

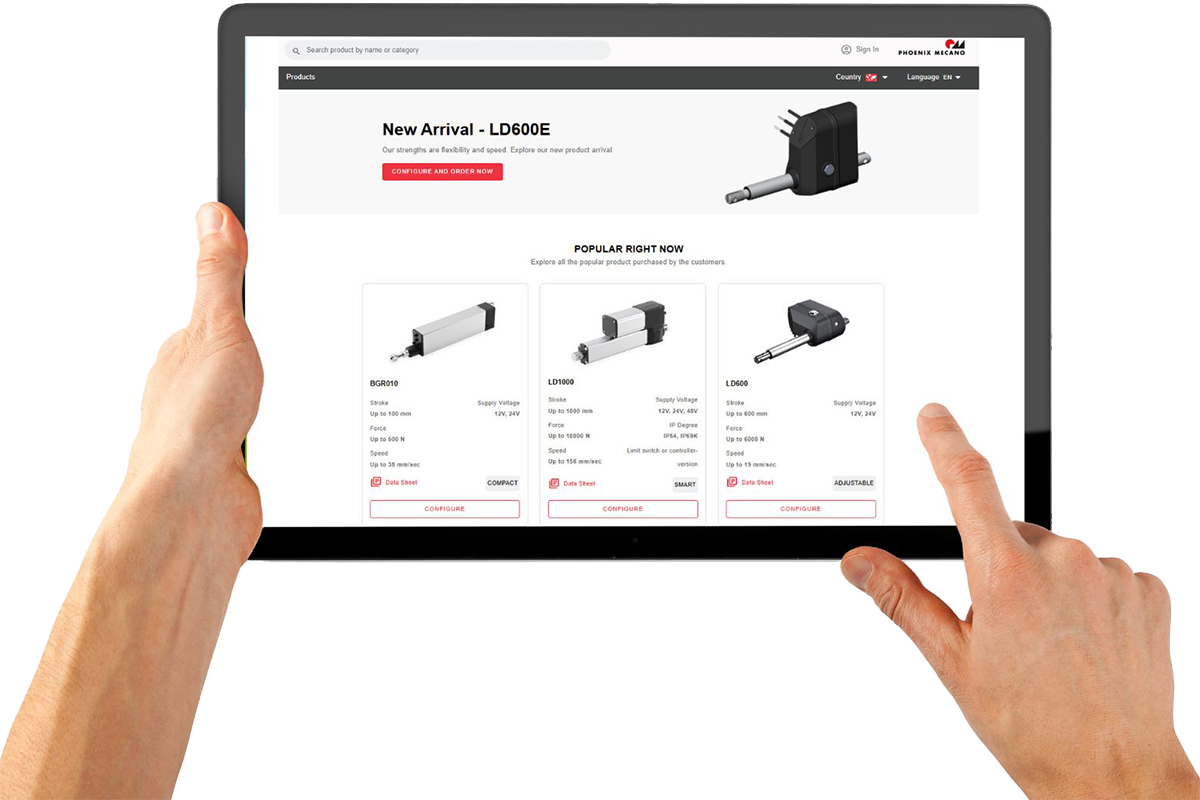

Configure Your Own Linear Actuator And Get The CAD Data

With our 3D CAD Product Configurator, you can create customized 3D STEP files for all our linear actuators to match your needs and requirements. The files are rendered and output directly, enabling you to incorporate them into your design and development processes. You receive the generated STEP files by e-mail. These can then be integrated directly into your application.

Start configuration

Guided through all steps

Get your CAD Data

Get an offer