)

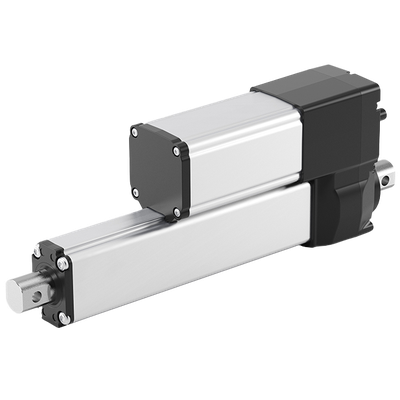

LD1000C Linear Actuator with Integrated Controller

Stroke: max.1000 mm | Force: max. 10,000 N | Speed max. 156 mm/s

Features

Protection class IP 69k static

Programmable start/stop ramps

Position feedback by absolute travel measuring system

Overcurrent shutdown

NRTL Certificate according UL 61800-5-1:2012/R:2021-02

LD1000C – The Smart Linear Actuator

The LD1000C linear actuator is a robust, high-performance solution designed for demanding application environments, offering up to 10,000 N thrust, 1,000 mm stroke length, and operating voltages of 12, 24 and 48V DC. With an integrated controller, precise position measurement system and individually adjustable parameters, it can be perfectly adapted to the application and can move up to eight drives synchronously. The linear actuator can be controlled in many ways, from a simple manual switch to an Arduino to a CAN-BUS. Customizable for various applications, it also features flexible movement profiles and adjustable speed, ensuring precision in even the harshest conditions.

The LD1000C’s durable die-cast aluminum housing and stainless-steel components offer IP69k protection, making it resistant to high-pressure cleaning, UV exposure, and extreme temperatures. This ensures reliable performance for industries such as agriculture, off-highway vehicles, marine technology and automation machinery adjustment.

Technical Data

General Data | |

|---|---|

| Force: | Max. 10,000 N |

| Speed: | Max. 156 mm/s |

| Stroke Length: | Min. 15 mm - Max. 1,000 mm |

| Installation Dimension (A): | Smaller than stroke 400 mm = stroke + 200 mm | Greater than or equal to stroke 400mm = stroke + 250 mm |

| Motor Voltage: | 12V, 24V, 48V DC |

| Degree of Protection: | IP 69k static |

| Duty Cycle: | 30% |

| Position Feedback: | Integrated Full Position Control via Analogue Signal and Digital CAN Interface |

| Synchronous Operation: | Up to x8 actuators |

| NRTL Certificate: | According to UL 61800-5-1:2012/R:2021-02 |

A variety of feedback options

Thanks to its integrated control unit and CAN interface, the LD1000C offers a variety of feedback options. The end position signals (digital outputs) can be used to control signal lamps, devices or relays. The analogue position feedback can be used for integrating into intelligent, complex control systems.

The absolute displacement measuring system opens up a wide range of control options and, in particular, enables the synchronous operation of up to six electric cylinders.

There is also high-resolution digital position feedback, which runs via the CAN interface. It records more than 4'000 steps per revolution, ensuring precision in the micrometre range when the position is queried via CAN.

An overview of the position feedback of the LD1000C:

Final position feedback

Absolute displacement measuring system

Analogue position feedback. Configurable according to customer requirements

Digital position feedback via the communication interface (CAN)

In addition to the position feedback, various parameters can be invoked via the CAN interface (operating voltage, motor current, position, status, etc.).

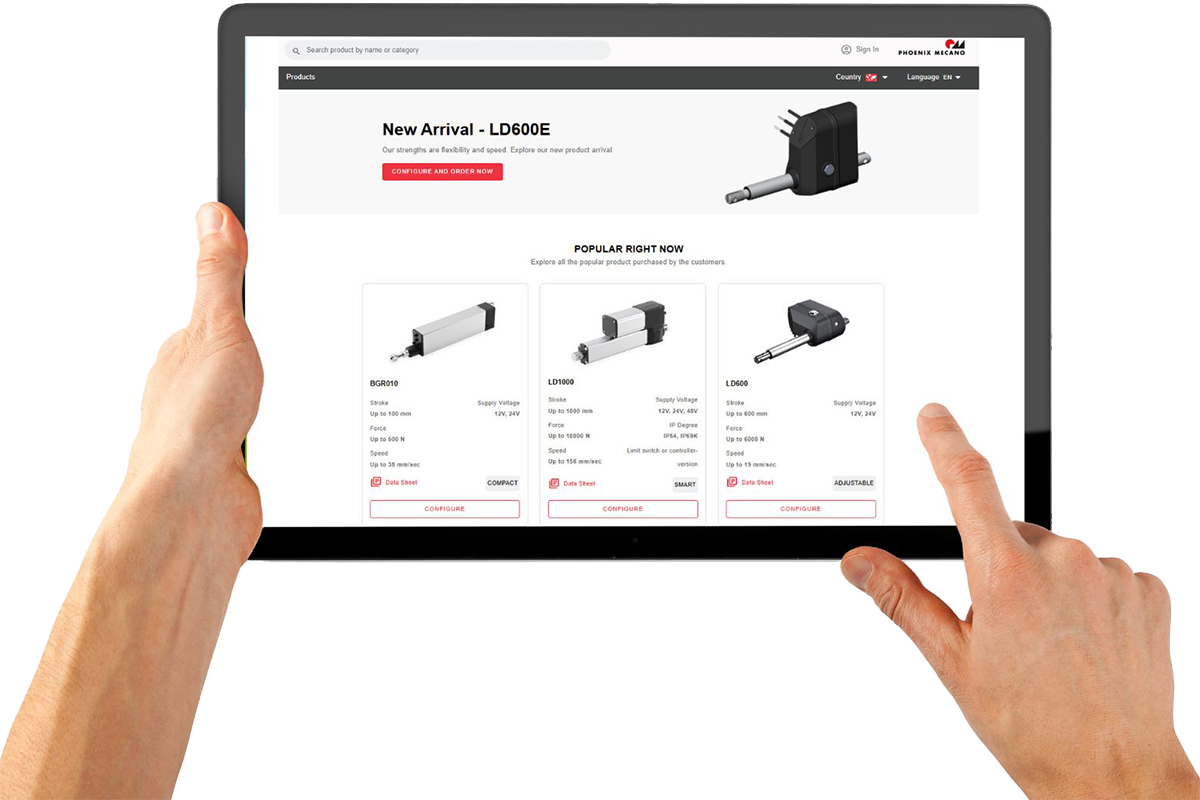

Configure Your Own Linear Actuator And Get The CAD Data

With our 3D CAD Product Configurator, you can create customized 3D STEP files for all our linear actuators to match your needs and requirements. The files are rendered and output directly, enabling you to incorporate them into your design and development processes. You receive the generated STEP files by e-mail. These can then be integrated directly into your application.

Start configuration

Guided through all steps

Get your CAD Data

Get an offer

)