1

Concept

Send us a sketch or CAD data, or let us visit you on-site to assess your requirements firsthand and develop a tailored solution for your machine housing

)

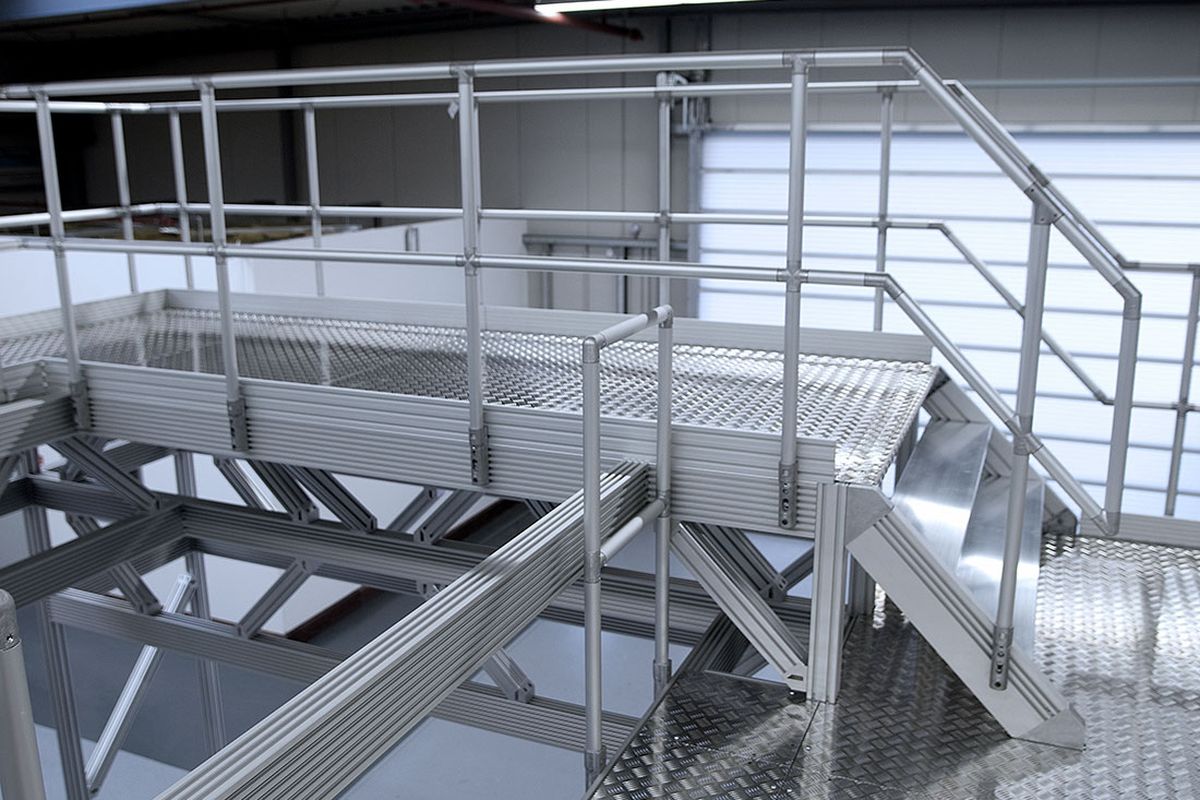

Industrial stairs and platforms with innovative profile and clamping system

Standard-compliant

High stability & low weight

Wide range of components

Easy access with quick-change principle

Whether large and complex or small and simple our industrial stairs, working platforms and industrial railings made of aluminium comply with the load and safety guidelines EN 1991-1-1 and DIN EN ISO 141221 as well as the accident prevention regulation (UVV) DIN 24530. And not only that. Our aluminium constructions also score points over welded systems.

They are significantly lighter and quicker to assemble with comparable stability. Above all, they are flexibly adaptable. Existing staircases and landings can be modified easily and without a great deal of time and effort and, unlike welding, without leaving any residue. This makes our industrial staircase and working platform system particularly suitable for areas where cleanliness is a key criterion.

The standardised construction elements (and available 3D files) of our industrial staircase and working platform modular system offer maximum flexibility and variability.

The special feature: no mechanical processing is required during assembly! The aluminium tubes, which are cut to length, are plugged together with tube connectors – also made of aluminium and screwed together in a force-locking manner.

The internal clamping mechanism of the tube connectors and special clamping screws ensure a frictional connection. Smooth contour transitions are convincing due to their pleasant feel and eliminate the risk of injury from catching on gloves or work clothing.

Work or machine areas that previously required additional securing can now be made accessible using the ITAS Quick-Change Principle, in just a few steps and without the need for time-consuming tools.

The quick-change system enables easier and faster assembly and disassembly of elements compared to conventional industrial guardrail systems. The cumbersome removal of entire railing segments is no longer necessary, making tasks such as loading and unloading with a forklift significantly more efficient.

Project Process

From simple staircases with railings to large, access-secured working platforms with ascents and transitions, we design and build your industrial stairs or platforms to meet your exact specifications. We assess the feasibility of your requirements and provide expert advice on possible optimizations. If desired, we support you from the initial concept to on-site installation, including custom color design and precise adaptation to your specific site conditions.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner