1

Concept

Send us a sketch or CAD data, or let us visit you on-site to assess your requirements firsthand and develop a tailored solution for your machine housing

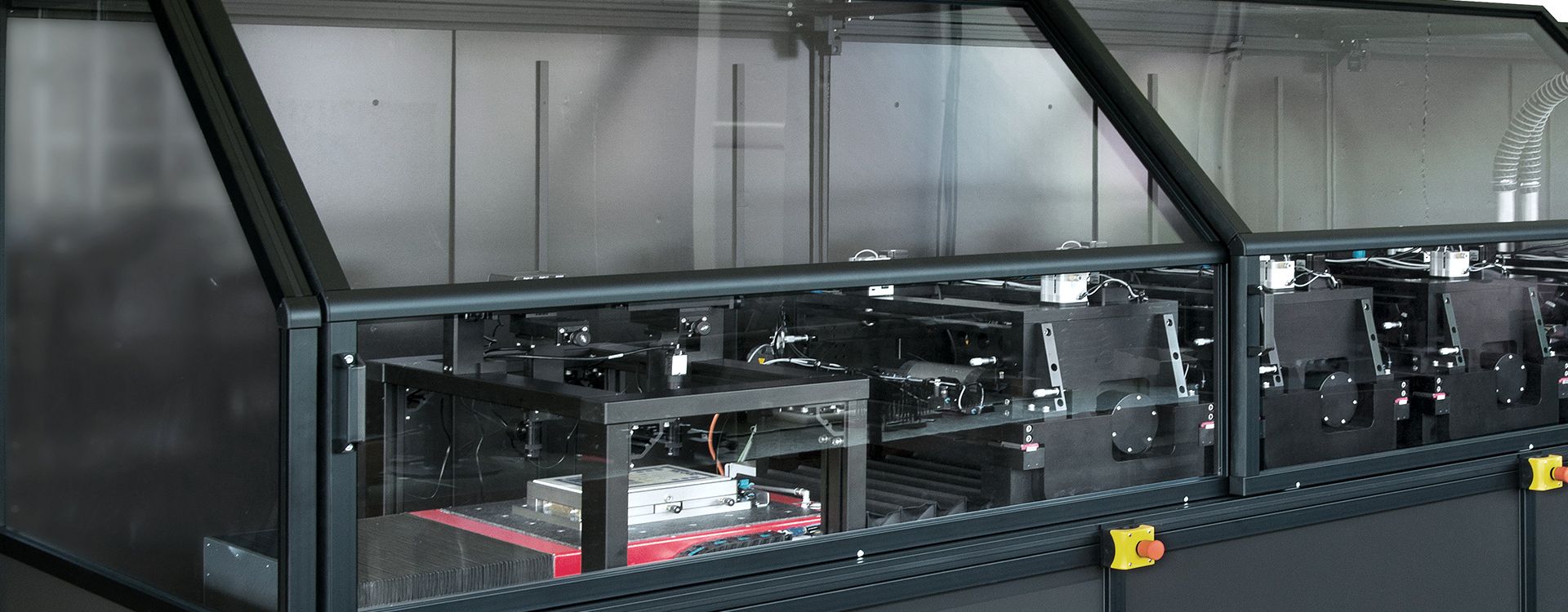

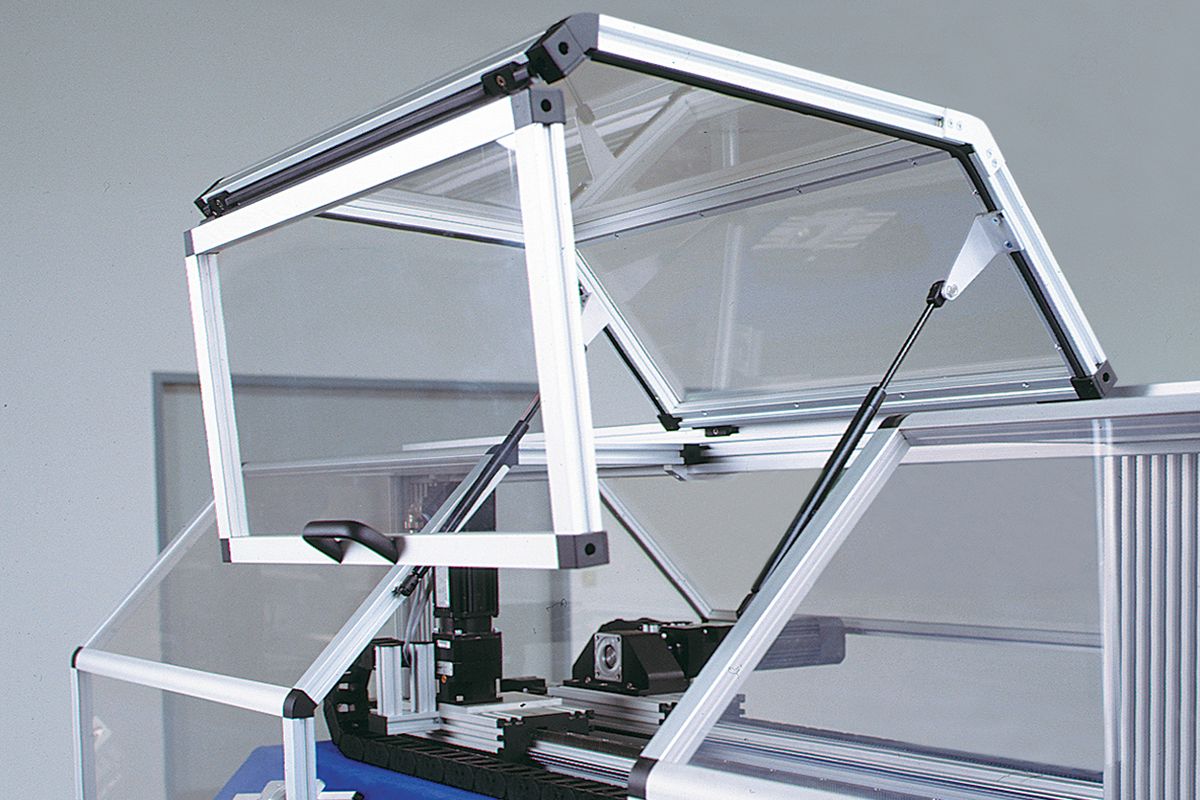

Safe and flexible machine housings with aluminium profiles. From the idea to the finished protective enclosure

Maximum flexibility

Paint finishes, functions & materials tailored to each machine

Anodised, attractive design

Industrial production facilities are often noisy and dirty. But this does not have to be the case. Custom-fit machine housings reduce noise and protect the machine from dirt, moisture and temperature fluctuations. In this way, they also protect and safeguard people, the machine and the production process. Functional machine housings thus ensure a clean, safe workplace and prevent accidents and costly production downtime.

And that's not all: machine housings also determine the look of a machine. Designed in your company's corporate design, they reflect your values and increase recognition value.

We offer a wide range of designs, which we cut to the required length with millimeter precision. In addition to standard aluminium construction profiles with profile grooves on all sides for optimum connection options, functional profiles with flat outer surfaces are also available.

These are particularly suitable for the food or food-related industry, as they offer little surface for dirt accumulation and are easy to clean. We also offer curved aluminum profiles on request. Precisely cut panels made of glass, Plexiglas, plastic, Alucobond or aluminium in various thicknesses are used as surface elements.

Project Process

Your machine layout and requirements define the framework conditions. We handle the detailed planning of the optimal machine housings! Your preferences and machine layout shape our approach to creating standard-compliant machine housings. Essentially, almost anything is possible! If you know exactly what you want and provide us with precise drawing specifications, we will implement them for you. However, we would prefer to develop the optimal housing for your machine together with you. To achieve this, our specialists will discuss all machine details, functions, and processes with you on-site and advise you on essential functional aspects such as maintenance access, doors, material bulkheads, and more. Afterward, we will take care of the drawings, manufacture the complete machine casing, assemble it for your on-site acceptance, and manage the entire logistics process.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner