1

Concept

Send us a sketch or CAD data, or let us visit you on-site to assess your requirements firsthand and develop a tailored solution for your machine housing

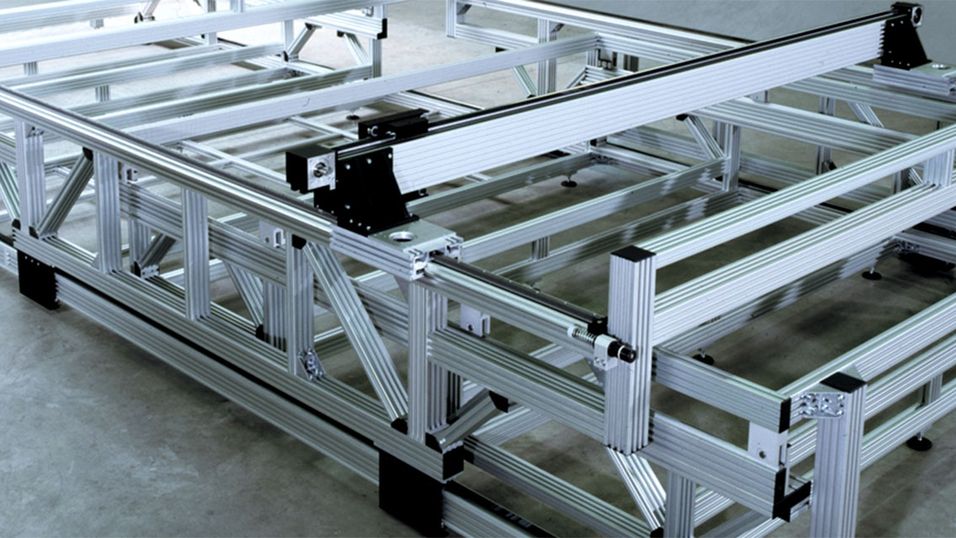

Stable and robust machine frames with aluminium profiles. The flexible alternative to welded machine frames

Tailored to the specific process requirements

Stable and flexible alternative to welded designs

Provide optimal connection points for the machine frame

Machine Frames

We supply machine frames and special constructions starting from a single unit up to large-scale series. The design and dimensioning of our basic frames, made from aluminium profiles, are tailored to the specific process requirements and the level of accuracy needed by the machine in question.

Constructions made from aluminium profiles offer a stable and flexible alternative to welded designs, even in heavy-load applications. The profile size is selected based on the loads involved, ensuring that technically sound designs provide a cost-effective solution.

Decisive advantages of our machine frames: they are lightweight yet robust, and so flexible that they can be adapted to changing process conditions at any time.

Our customer-specific machine frames are based on a comprehensive modular profile technology system. At the core are anodised aluminium profiles in over 100 different sizes and cross-sections, ranging from 20 to 320 mm, all of which are fully compatible with one another.

The construction profiles, featuring grooves on all sides, provide optimal connection points for the machine frame, enabling virtually unlimited application possibilities.

The modular system also includes a wide range of accessories, such as flange strips, angles, and cover caps as well as cover strips for concealing cables and lines along the profile grooves, or gusset plates for additional stability.

Project Process

Together, we will develop your machine frame. You define the requirements, and we handle the rest: we review your drawing specifications, suggest optimization options, select the appropriate profile sizes based on load requirements, and include the necessary accessories. We then cut the profiles to size and manufacture the machine frame according to the parts list. If desired, we can also design a suitable base frame for you. Want to assemble it yourself? No problem, the cut profiles are easily connected using flange strips, with no drilling required. This approach saves both assembly time and costs.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner