1

Concept

Based on your task and the prevailing environmental conditions, we develop and individual solution that meets your requirements perfectly.

Increase your productivity in intralogistics with Autonomous Mobile Robots from MiR

Relief of The Employees

Payback in 1-2 Years

Delivery and Collection on Time

With the driverless transport systems from Mobile Industrial Robots (MiR), Phoenix Mecano offers autonomous mobile robots that stand out for their versatile and flexible application options and user-friendly operation.

The AMRs from Mobile Industrial Robots are versatile in use and flexible in design. MiR robots can be equipped with various add-on modules developed by MiR. These products offer a CE-certified complete solution from MiR. If no suitable add-on module is available, we will create a custom solution as your integrator to meet your specific needs, ensuring the application is perfectly designed for your requirements. Whether for industry or the healthcare sector, we provide tailored solutions.

Our goal is to drive economic automation and increase productivity in your intralogistics. The mobile robots often achieve payback within the first year.

There are many terms in the field of autonomous transportation systems. One common term is AGV, which stands for Automated Guided Vehicle. These transport systems require guidance to navigate, often through rails, markings, or magnetic strips embedded in the ground, restricting them to predefined routes.

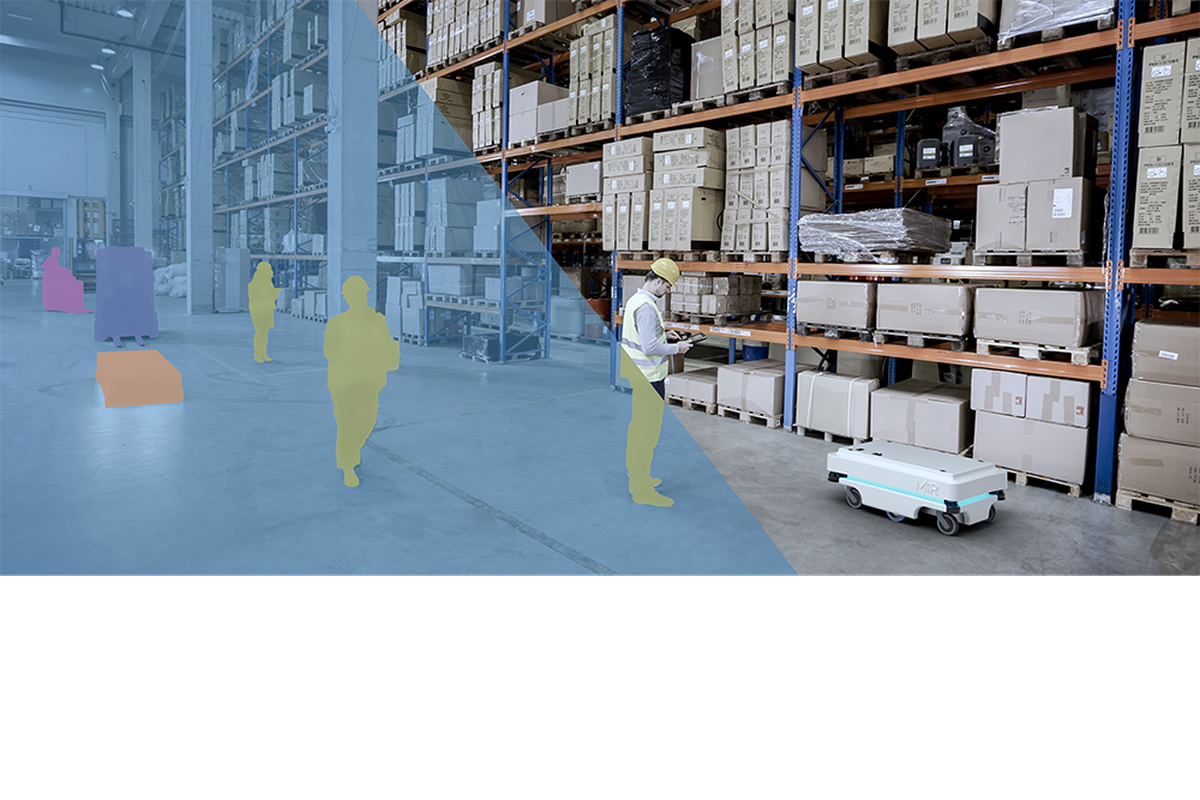

MiR's driverless transport systems are known as autonomous mobile robots (AMRs). Compared to conventional AGVs, AMRs offer the advantage of self-navigation using sensors and cameras, making them highly flexible in terms of route finding. They autonomously avoid people or objects and orient themselves using a captured map of the environment. This makes AMRs an ideal choice for transitioning to automated guided vehicles without needing to modify your production infrastructure.

Obstacle Avoidance: AMR robots independently avoid people and objects

Autonomous Navigation: The AMR navigates using cameras and sensors

No Infrastructure Modifications: The AMR requires no markings or rails for navigation

Thanks to SICK laser scanners, 3D cameras, and proximity sensors, no external navigation systems or guidance aids are needed for navigation. Integrated collision detection ensures the robots work safely and efficiently in dynamic environments alongside your employees. The robots avoid people and objects, continuously orienting themselves to a captured environment map.

The environment map and work missions are managed in the user-friendly, web-based software. No programming knowledge is required to operate the AMR, ensuring quick and easy implementation in your plant. The software is accessible via WLAN from a mobile device, such as a smartphone or tablet, or from a PC. The management and control of multiple AMRs is done via MiR Fleet Management.

Project Process

Products and Accessories for AMRs from MiR

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

References

"Throughout the project, Phoenix Mecano stood by us as a reliable partner and successfully supported us in using AMR robots to speed up material supply and relieve the burden on internal logistics."