We don’t accept limits

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

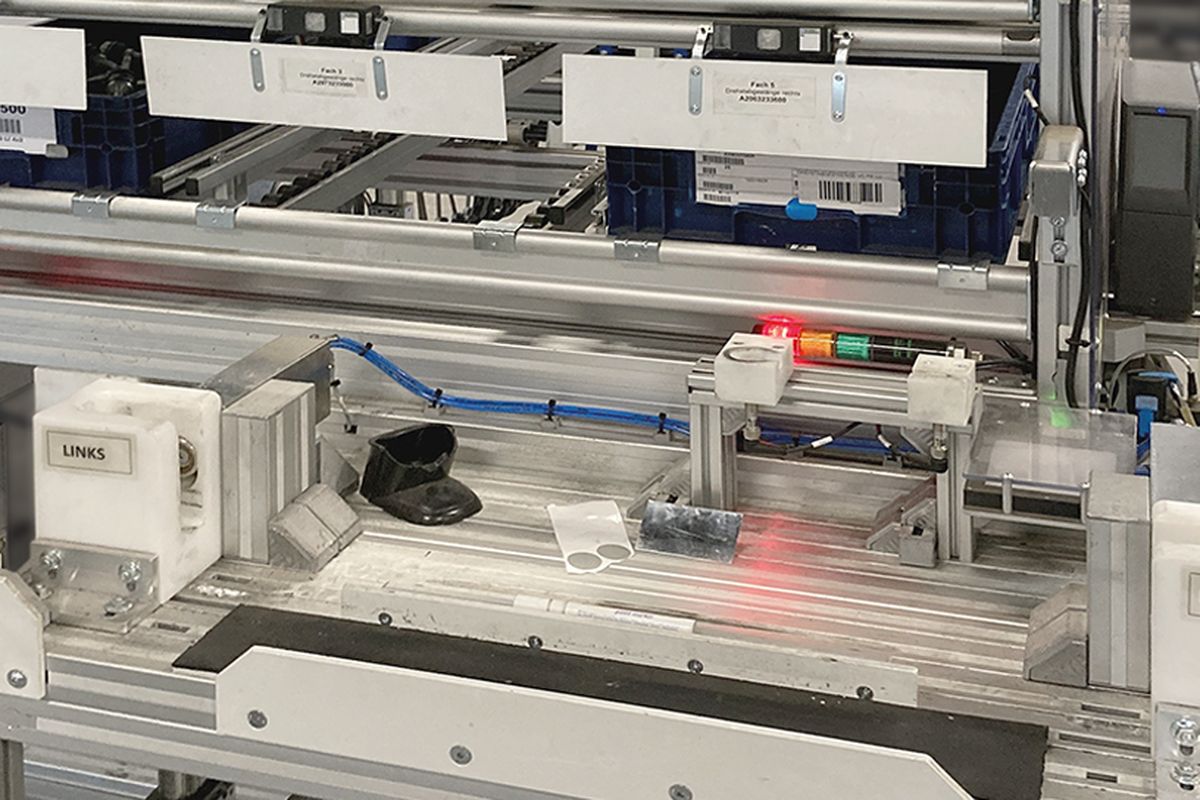

Cognitive Camera-Based Assistance System for manual workbench systems

Minimal Employee Training Required

Integrated Assembly and Real-Time Quality Checks

Consistent Working Instructions and Inspections

Increased Productivity and Reduced Fault Rate

Cognitive assembly assistance systems are known for solving complex tasks based on the given situation. Sensors provide relevant ambient data, which is combined with the stored knowledge of the assistance system to assess the current situation and determine the optimal approach.

The Benefits of the Cognitive Assistance System at a Glance

Training for employees, even with a large variety of variants, is reduced to a minimum

Assembly and real-time check in one working step

The current work instructions and inspection procedures are always used and observed

Prevention of rejected goods, repairs, claims, and certified traceability

Productivity increases – the fault rate drops

Cognitive assistance systems are used in assembly to guide employees in production and ensure that working steps are carried out correctly in real time. In this field, we rely on a sophisticated and proven assistance system. This cognitive system utilizes camera images, industrial image processing algorithms, and artificial intelligence. The camera images captured in real time at the workbenches are continuously analyzed by the assistance system and digitally combined with the stored specialist knowledge.

The assistance system uses the data and results from this cognitive process to generate guidelines tailored to the specific situation. When an assembly step is completed correctly, the system triggers the next step and provides new instructions. However, if an error occurs during assembly, it is immediately flagged with the corresponding alerts.

Another significant benefit is that this cognitive assistance system enables paper-free production control. The image and analysis data, which remain accessible, can be stored by the assistance system for documentation purposes.

In the incoming and outgoing goods departments, a chamber-based assistance system supports employees by automatically identifying items that are difficult to distinguish (auto-ID). Another application of the assistance system is the automatic optical inspection (AOI) of products in the incoming goods inspection, outgoing goods inspection, and final inspection on the production line.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.