We don’t accept limits

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Complete assemblies from a single source

Assembly Service

Own production resources are expensive, and planning is a challenge. Many companies experience fluctuating staffing needs or simply want to focus on their core competencies.

With ever-changing production demands, a flexible partner can be a practical alternative to in-house production. We produce for many well-known companies – over 90% of orders leave our premises as fully assembled sub-assemblies. As a proven lean production specialist, we streamline one-piece flow processes to ensure high efficiency and simplicity.

Benefits

Single-Source Partnership: One contact for your complete order

Just-In-Time Delivery: Lower warehousing costs

Cost-Effective Assembly: Lean, one-piece flow processes

Quality Assurance: We ensure the desired quality

Fully Assembled: Over 90% of orders are complete

Versatile Options: EMC, cleanroom, LEAN, collaborative robotics, and pick-by-light

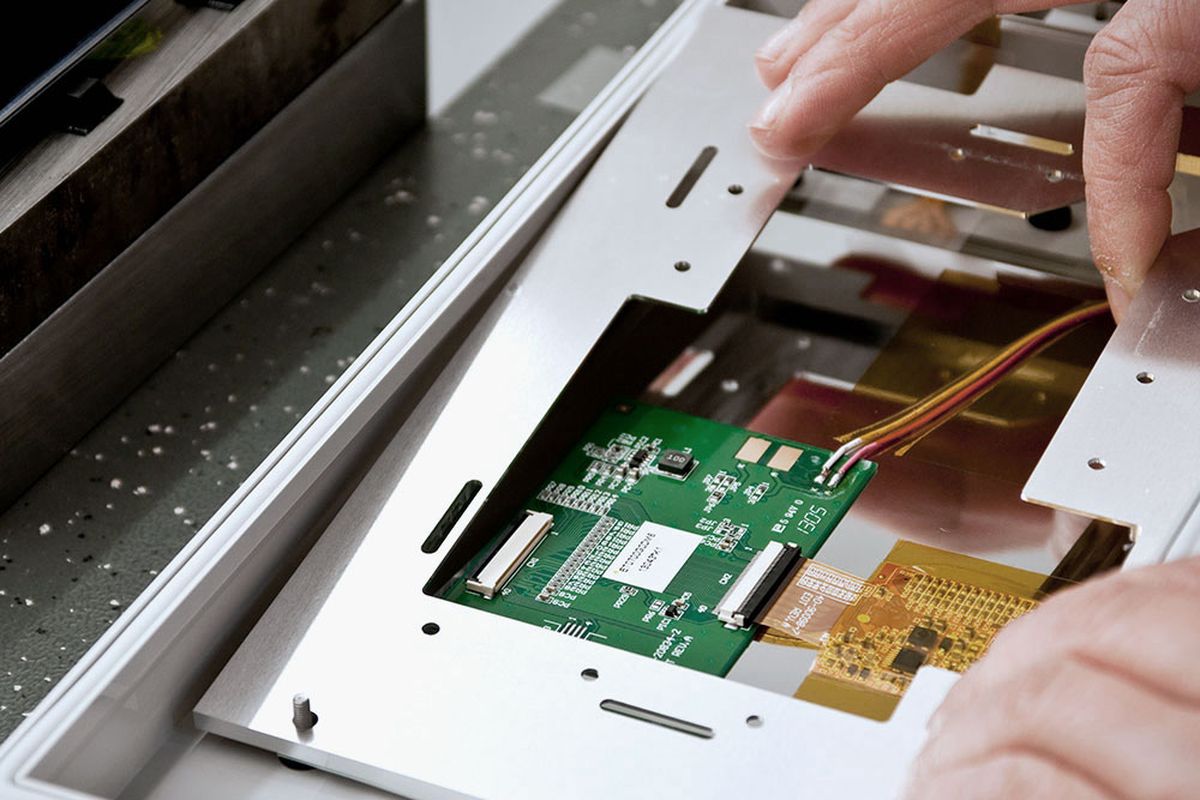

We assemble the complete product for you – including testing and packaging if required. Whether it’s the assembly of a membrane keyboard, integration of a display and touch screen, or the installation of PCBs or your electronics in the enclosure, we can help. You can supply the components, or take advantage of our procurement service.

We assemble your device in one-piece flow on our specially equipped LEAN assembly workbenches. Supported by a pick-by-light guidance system, we guarantee consistent quality. Whether in small or large quantities, our workstations are set up quickly and flexibly, and we deliver the assembled enclosure just in time.

Everything from a single source

EMC and cleanroom assembly

Terminals and cable glands

48-hour service

Electronics and PCB assembly

Testing and packaging

Save time on assembly and the tedious sorting of profiles and sliding blocks. Our team assembles aluminium profiles with impressive speed.

From assembly workbenches and machine frames to stair systems and safety guards, we build exactly what you require based on your drawings. We also procure external components such as separating plates or corrugated grids, while offering in-house profile processing and custom lacquering.

This ensures short lead times and eliminates the need for costly transport to external suppliers. Over 90% of our customers already benefit from our profile assembly service – you can too!

Assembly workbenches

Machine enclosures

Protective grids

Shelves and trolleys

Stair systems

Machine frames

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

Advice from our experts

A plan tailored around you

Answers to all your queries