We don’t accept limits

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Engineering

As a provider of solutions in customised enclosures, profile technology, shop floor, and linear technology, we are committed to giving you a competitive advantage through our specialised expertise.

Our engineers develop solutions based on your requirements and produce detailed technical drawings and 3D CAD models. Whether you are in the early stages or further along in development, we can offer support or take over an entire component.

Regular updates and transparent communication with our design team ensure you remain informed throughout the process.

Benefit from Our Engineering Services

Specialist expertise in our product areas

40 years’ industry experience

Innovative solutions delivering competitive advantages

Experience shows that many companies focus on the electronics during development while neglecting the enclosure as the packaging for these components. However, unexpected costs can arise later during the development of injection-moulded or die-cast enclosures, ultimately increasing the product cost. We recommend addressing the integration of electronics and display elements at an early stage.

Moreover, tooling production is expensive; therefore, components must be optimally designed to minimise the need for tool changes. We have the expertise and facilities to develop such parts using injection moulding and die casting processes. Close collaboration between development, rapid prototyping, tool-making, and series production is essential for fast, cost-effective, and successful implementation.

Increasing Productivity and Reducing Lead Times

We are driven to boost productivity and shorten lead times for our customers. As a manufacturing company that has been optimising and digitising its own production in line with LEAN principles for years, we understand the challenges you face.

Tailored Production Process

Leveraging our expertise, we develop solutions that enhance your production process. We begin with a comprehensive process analysis that guarantees improved productivity. Our approaches include LEAN live workshops, material handling via transport robots, LEAN assembly workbenches supported by pick-by-light and collaborative robots, and the implementation of paperless orders and monthly instructions.

Custom Assembly Workbenches

Our workbench solutions are individually designed and built to meet your product’s specific production requirements.

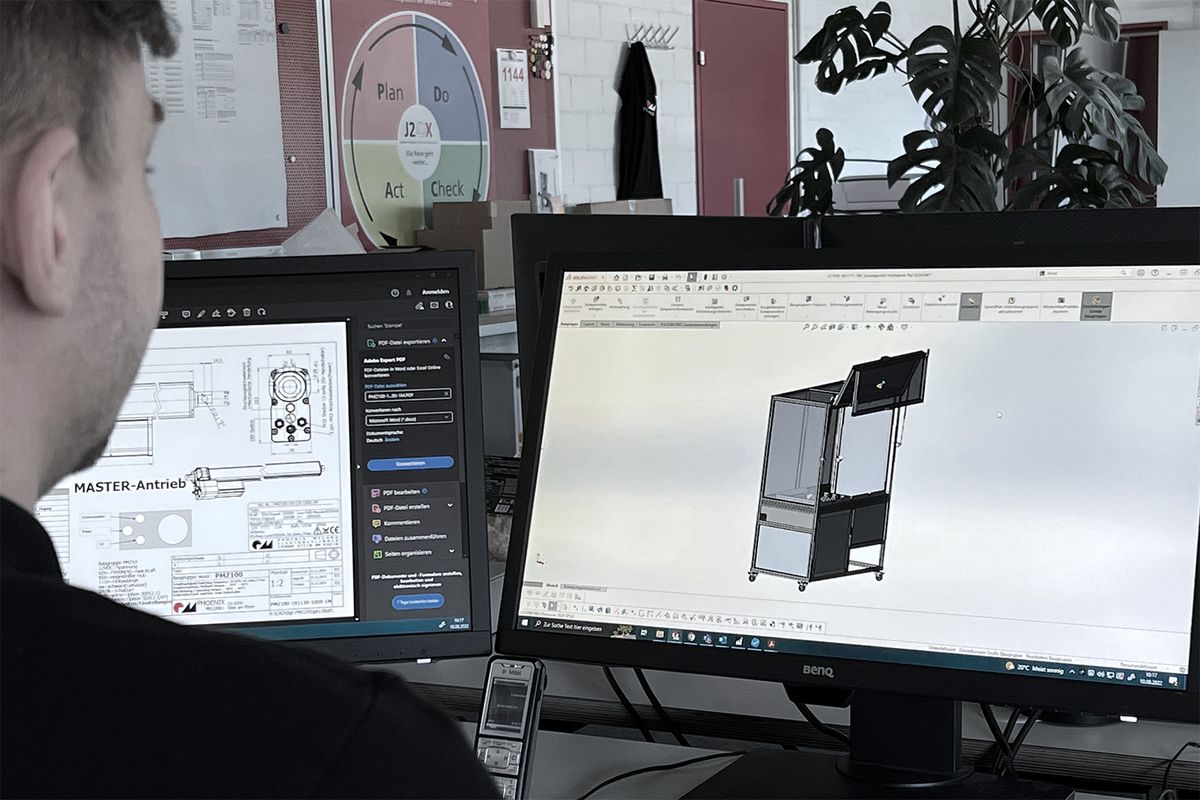

We support our customers in the design and selection of aluminium profiles. Whether you have a finished CAD design or just a sketch, we work together to identify optimisation potential and reduce costs.

Our technicians can visit your site to record requirements and dimensions, or you can send the information via email. Our designers then develop a final solution in CAD that complies with standards such as DIN EN ISO 14120 and the Machinery Directive 2006/42/EC.

Once you have reviewed and approved the design, we produce production drawings and parts lists for third-party components, surface elements, or adapter plates.

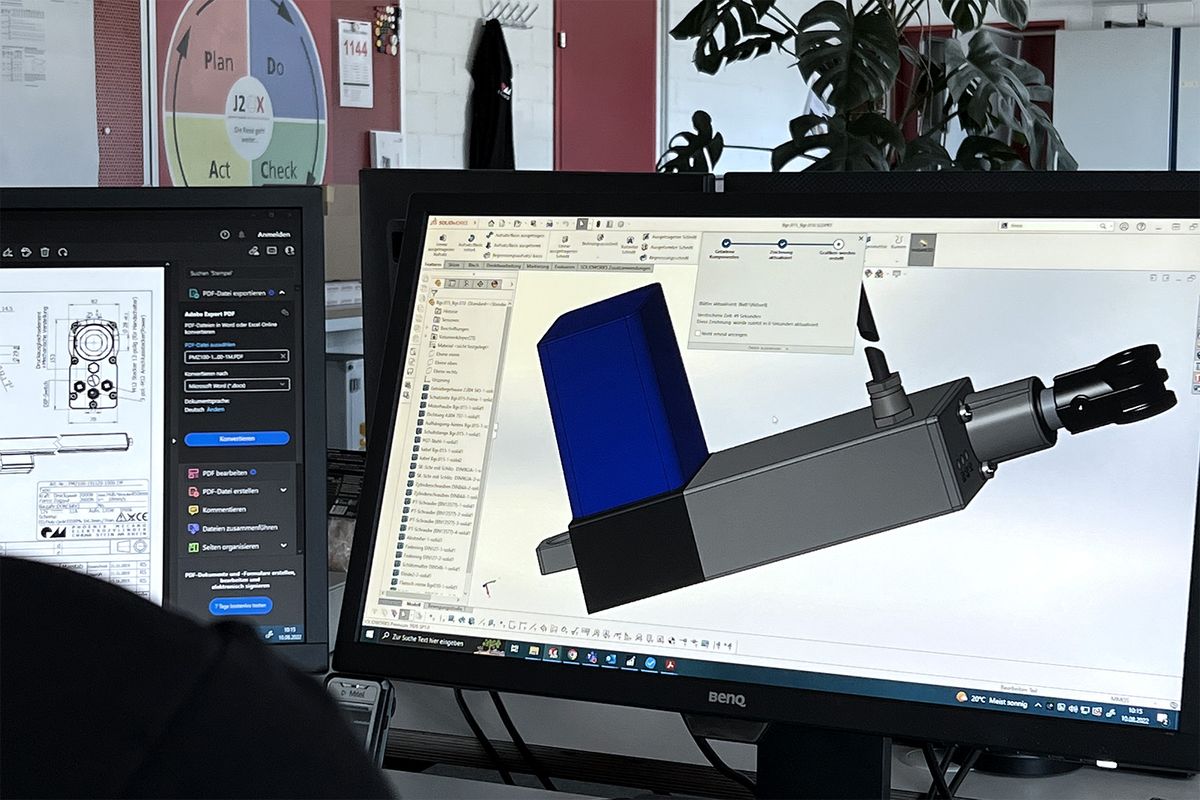

For more than four decades, Phoenix Mecano’s innovative approach has been supported by a team of experts who develop technologically advanced acuators and lifting columns from concept through prototype to series production, with meticulous attention to detail.

We pride ourselves on flexibility and a customer-centric approach. Our electric cylinders offer highly customisable solutions to meet every need.

Our engineers support you throughout all project phases – from requirements analysis and planning to design, implementation, testing, operation, and support – ensuring optimal results by combining expertise from various industries and technical fields in mechanics and mechatronics.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

Advice from our experts

A plan tailored around you

Answers to all your queries