Lukas Limacher

Co-Founder & CEO, AIRICA AG

Plastic Injection Molding

Plastic Injection Molded Parts

Whether innovative start-ups or companies excellent established on the market - anyone who needs injection molded parts for their equipment is dependent on good professional support. The focus is not only on the design of the housings and components. Important details such as optimum durability, hygienic properties, ease of assembly and a reasonable price have a strong impact on the end product and its success on the market.

We accompany our customers in the complete process around injection molding technology from the idea to the serial production of your end product including assembly and shipping. Simply ask our product specialist for detailed expert advice on your ideas. We step in with our expertise exactly where it makes sense and is desired for your project.

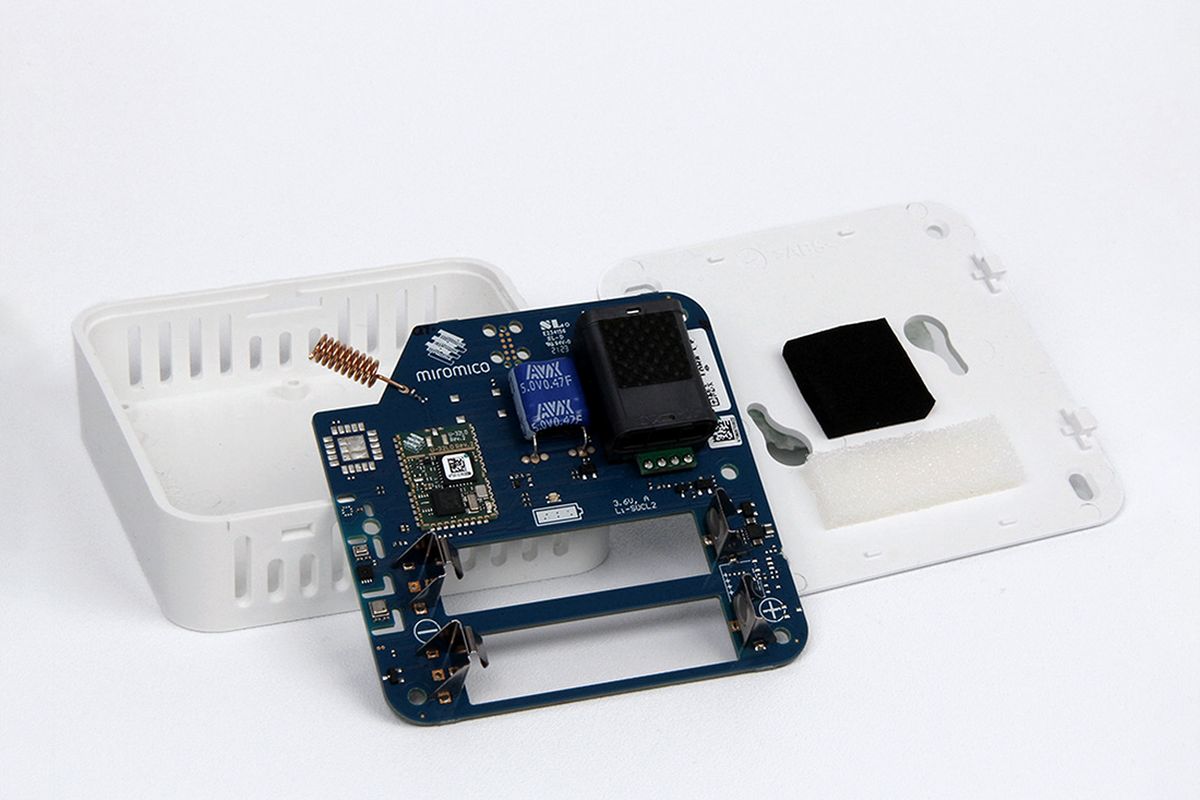

Developers of electronic and electrical devices often focus on the "inner values" of innovative products – such as software, electronics, switching elements, displays, and circuit boards. Designing the appropriate enclosure is one thing; producing the first prototype, building the mould, and later manufacturing an entire series of injection-moulded parts is quite another. Early prototypes may not meet requirements, and the injection-moulded parts might fall apart or exhibit sink marks on the material surface. In the worst case, the enclosures are designed in such a way that the parts cannot be produced economically – or at all – or defects are not discovered until the devices are already on the market. If, for example, the mixtures for the material, the seal, or the clearances in the mould are incorrect, this can lead to costly manufacturing defects. The delays in bringing the product to market associated with these errors can cause an explosion in costs.

What customers say about us?

Co-Founder & CEO, AIRICA AG

Services and Process Flow

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

Success Stories