We don’t accept limits

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Agile and flexible intervention from the very start

Rapid Prototyping

Using 3D rapid prototyping, design errors are detected early, which reduces development time and shortens time-to-market while enhancing design quality and increasing flexibility.

Experience in Additive Manufacturing

Leverage our extensive expertise and the versatility of various additive manufacturing processes to your advantage.

Depending on your application’s requirements – such as surface finish, accuracy, volume, or material – we select the most suitable 3D printing process. Whether you need demonstration models, functional prototypes, pilot series, or exclusive small batches for field tests, we support your development by producing prototypes based on 3D data quickly, cost-effectively, and tailored to your needs.

Insights from tests and pilot series are then integrated directly into development and tool making, ensuring a short time-to-market and significant cost savings.

Stereolithography (SLA) is an additive manufacturing process that uses a liquid resin cured by laser irradiation. The resulting 3D prototypes offer high accuracy, excellent detail resolution, and a smooth surface finish, making them ideal for functional testing, fit checks, and design-focused applications. However, the process requires support structures and is generally more expensive and slower compared to SLS.

High accuracy

High-precision functional models

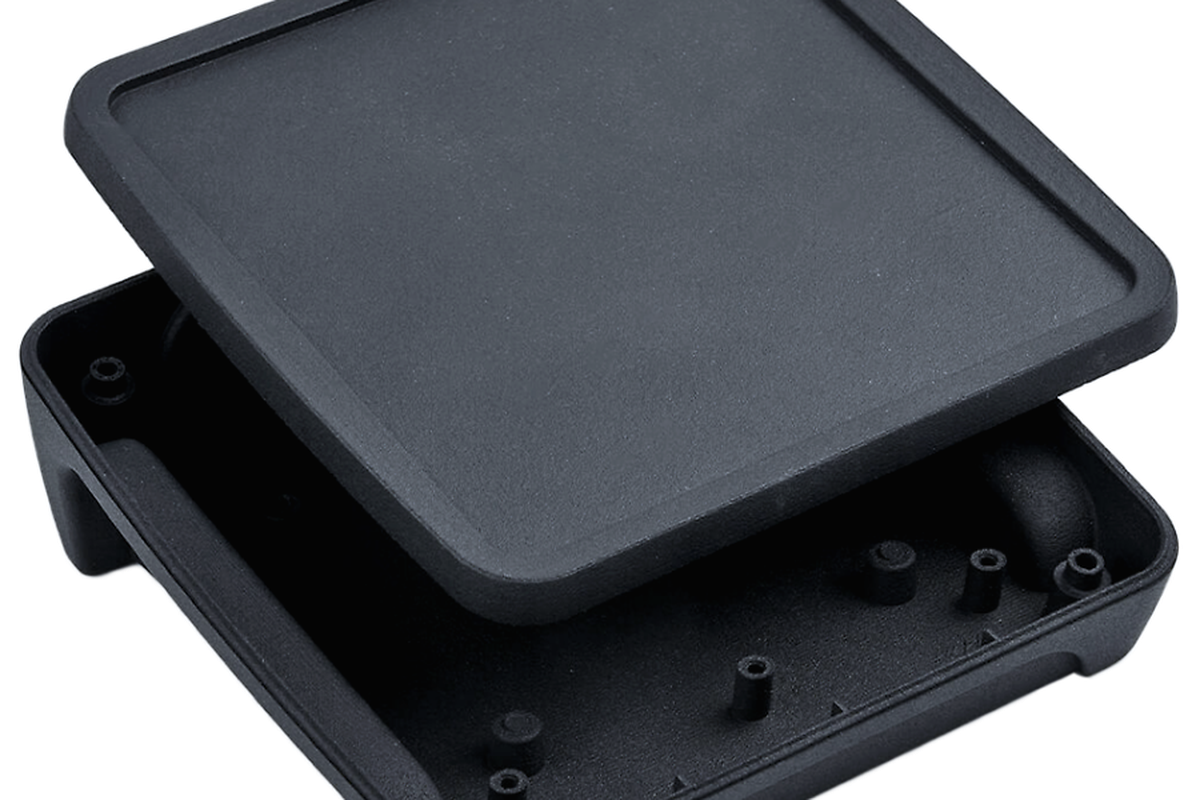

The SLS rapid prototyping process utilises a powder-based starting material (such as plastic, wax, or sand) to create the desired shape by fusing the particles together. A laser is activated at precise locations to melt the powder, which then re-solidifies upon cooling. Without the need for support structures, highly complex geometries can be printed. SLS is cost-effective and well-suited for prototypes, functional tests, and pre-production runs. While the resulting parts are strong and lightweight, the surface finish is rough, and exact tolerances may not be achieved.

Complex shapes

Functional tests and pre-series

In the FFF/FDM 3D printing process, a solid filament (ABS, PLA, PETG, etc.) is melted in the print head and extruded layer by layer to form the desired part within the printing chamber. This method is ideal for early functional tests, offering low-cost and rapid production. However, the resulting surface is rough due to the staircase effect and often requires support structures, depending on the part's geometry.

Cost-effective and fast

Rough surface

Multi Jet Fusion (MJF) is a powder-based 3D printing process that achieves high density and reduced porosity compared to laser sintering. It produces high-precision parts with smooth surfaces that closely mimic injection-moulded components. In this process, powder particles are sprayed with a heat-conducting agent, then heated and fused together.

High-precision parts with smooth surfaces

High stability and load capacity

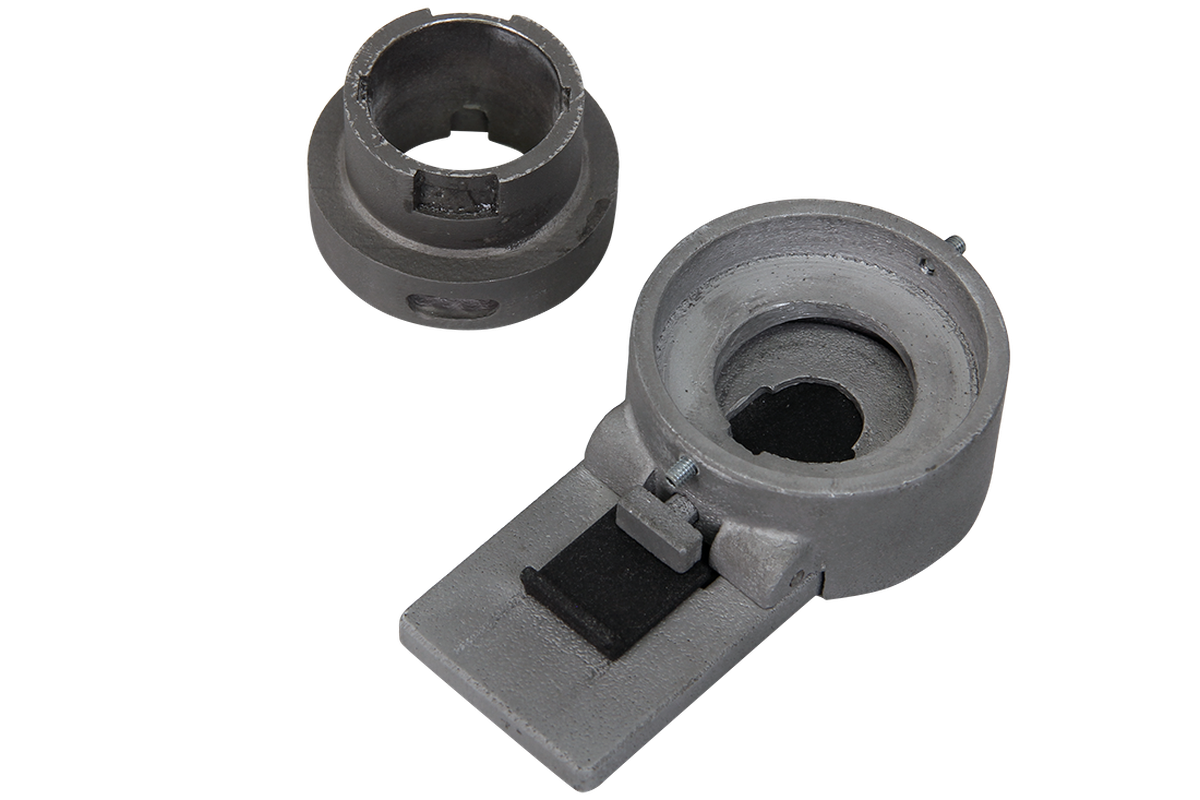

A thin layer of metal powder is selectively melted by a laser, building the mould layer by layer. Metal laser sintering can produce shapes with more complex structures than milling from solid material. Thanks to its higher strength, this 3D printing process is well-suited for prototypes that demand higher quality, as well as for small series production.

Complex structures possible

For small and pilot series

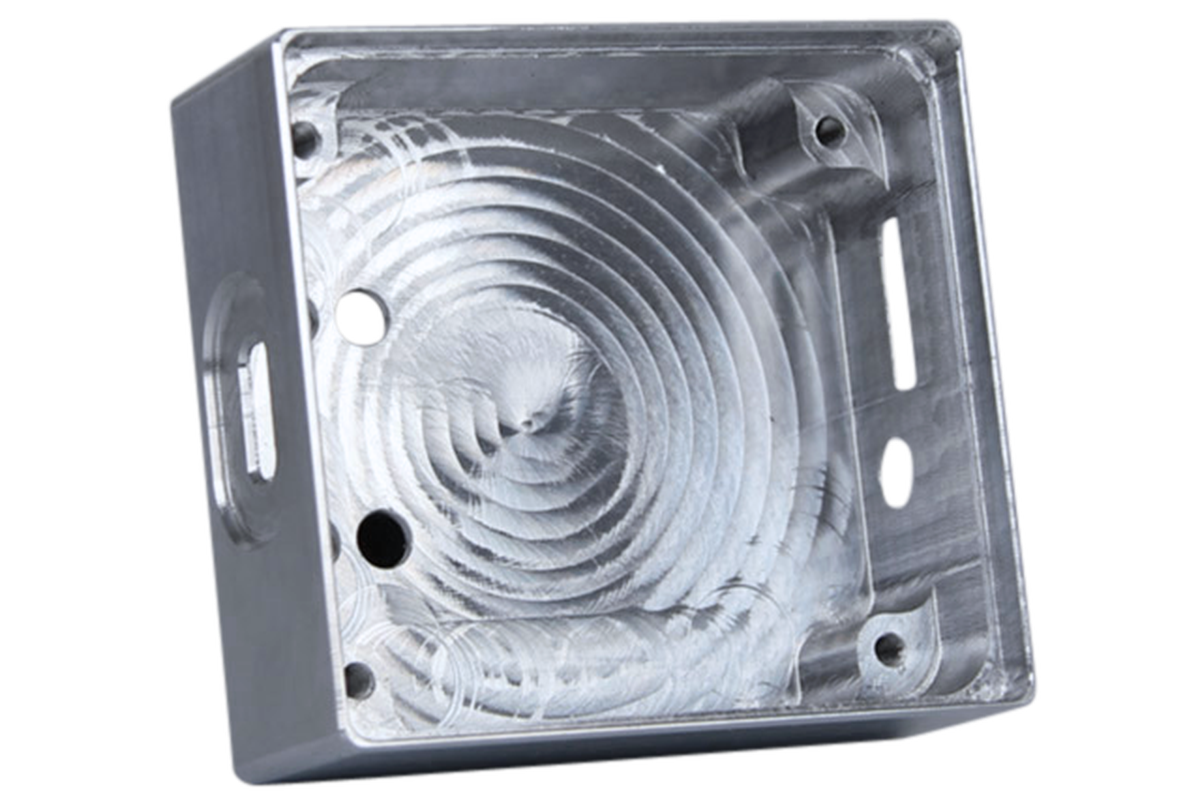

As an alternative to metal laser sintering (MLS), die-cast aluminium housing prototypes can be milled from solid aluminium for field tests or pilot series. We have an extensive range of machinery for this process, which offers higher tolerances and finer surface finishes compared to MLS. It is also faster, more cost-effective, and the material properties closely resemble those of the final series product.

High tolerances and fine surfaces

Suitable for field tests or pilot series

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

Advice from our experts

A plan tailored around you

Answers to all your queries