We don’t accept limits

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

We make your production flow

Customised internal material systems

Reducing throughput times and inventories

As is well known, transport does not add value in the sense of LEAN thinking, and therefore, no one is willing to pay for it. However, logistics cannot be eliminated from a company. In LEAN logistics, the goal is to make logistics as efficient as possible while keeping it as minimal as necessary. The focus is on controlling and designing logistics processes to reduce throughput times and inventories while maintaining process reliability and delivery readiness.

In LEAN logistics, we focus on internal transport, processes, and visualisation. We provide solutions and products designed to make internal workflows and material movement leaner and more efficient, enabling employees at the assembly workstation to work free from waste.

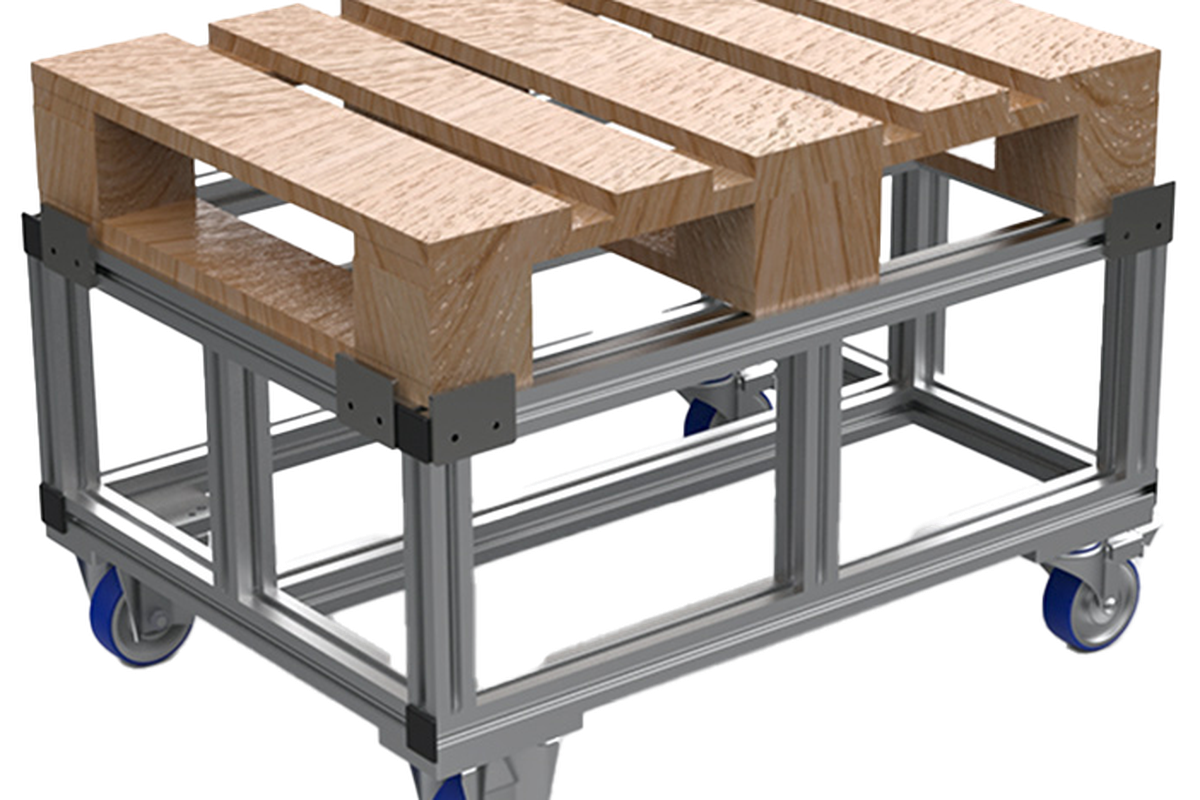

We develop material transport carts, flow racks, and pallet carts tailored specifically to your product, which are integrated directly from the warehouse or production area into the relevant assembly line. The goal is to minimise inventory levels, avoid unnecessary material transfers, and ensure compliance with the FIFO (First In, First Out) principle.

Material transport carts ensure smooth internal transport from department to department, such as from production to the paint shop or assembly. Individually developed for your product and process flow, they eliminate the need for reloading before the next work step.

Depending on the work environment and process flow, transport trolleys may need specific features, such as closed profiles for increased hygiene standards, heat-resistant rollers for drying rooms, or an ESD design to prevent electromagnetic charging.

The Material Cart Eco is designed for efficient, ergonomic handling of goods within production and assembly areas. Its lightweight yet stable aluminium frame ensures easy movement and durability in daily use.

Adjustable shelves and handles provide flexibility, while the clean design supports structured, lean workflows. An ideal choice for intralogistics that demand efficiency and reliability.

For efficient and uninterrupted production on an assembly line, flow racks are essential. They are designed to be loaded with containers from one side while materials are retrieved from the other.

Empty containers are discharged to the rear via a roller conveyor or tray and then refilled through the logistics process. Our flow racks are customized to fit specific workstations, depending on container and material sizes.

To prevent mix-ups and reduce search times during assembly, we recommend using our SETAGO® Pick by Light system.

This sophisticated system visualizes material stock, simplifying just-in-time production. Kanban operates on the pull principle, meaning the consumer takes the material they need, and the supplier automatically replenishes it when the minimum quantity is reached.

Minimum stock levels are marked with arrows, making it immediately clear when reordering, delivery, or production is necessary

Panels on the top bar provide space for labeling or illustrations

Modular aluminum profile system for flexibility and adaptability

Material feed and removal possible from both sides

Intra-company transport and material handling play an essential role in logistical success. Increase your productivity in intralogistics with automated guided vehicles from Mobile Industrial Robots. The AMRs from Mobile Industrial Robots are versatile and customizable.

For example, MiR robots can be equipped with various attachment modules developed by MiR, providing a CE-certified complete solution.

If no suitable add-on module exists, we, as an integrator, will develop a custom solution tailored to your specific application requirements. The mobile robots often achieve a payback within the first year.

From container and shelf labeling to floor markings – high-quality visual management products make it easy to organize any production clearly.

At Phoenix Mecano we don’t simply sell products and offer services. We constantly push for more: high-quality hardware and software products that can go further, process innovations that open up new opportunities, customized solutions that supercharge productivity. Here’s how we make much more possible for our customers:

When it comes to what’s possible, our engineers and designers can help you see beyond today’s limitations, to new potential.

Whether it’s supporting your new product designs or reimaging your assembly operations, our team is with you for the journey.

We come from a long Swiss and German engineering heritage and are proud of our culture for always seeking engineering excellence.

As technology transforms the manufacturing landscape, we bring you the deep expertise and industry leading partners that make innovation feel natural.

Our team brings many years of expertise working across sectors as diverse as Agriculture, Healthcare, Maritime and many more.

Our service led culture makes us the perfect partner whether you’re simply looking for a one-off product or a supply chain partner.

References

“The support and advice received from Phoenix Mecano throughout the project was very professional. I also thought the LEAN Live Workshop at Phoenix Mecano was great. We have learned a lot, which will also benefit future projects.”