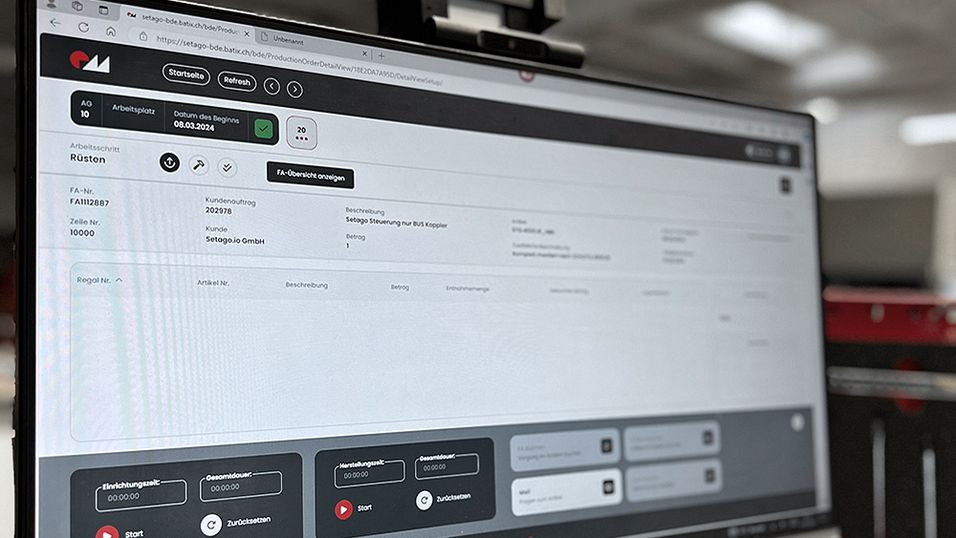

1

Describing The E-paper

The e-paper is described with the order data and runs with the material. It identifies the order and the goods so that it is clear which order the material belongs to. The e-paper is optional. Of course, an order paper with a parts list can still be used for identification. However, you will then not benefit from the advantages of live data, for example

)